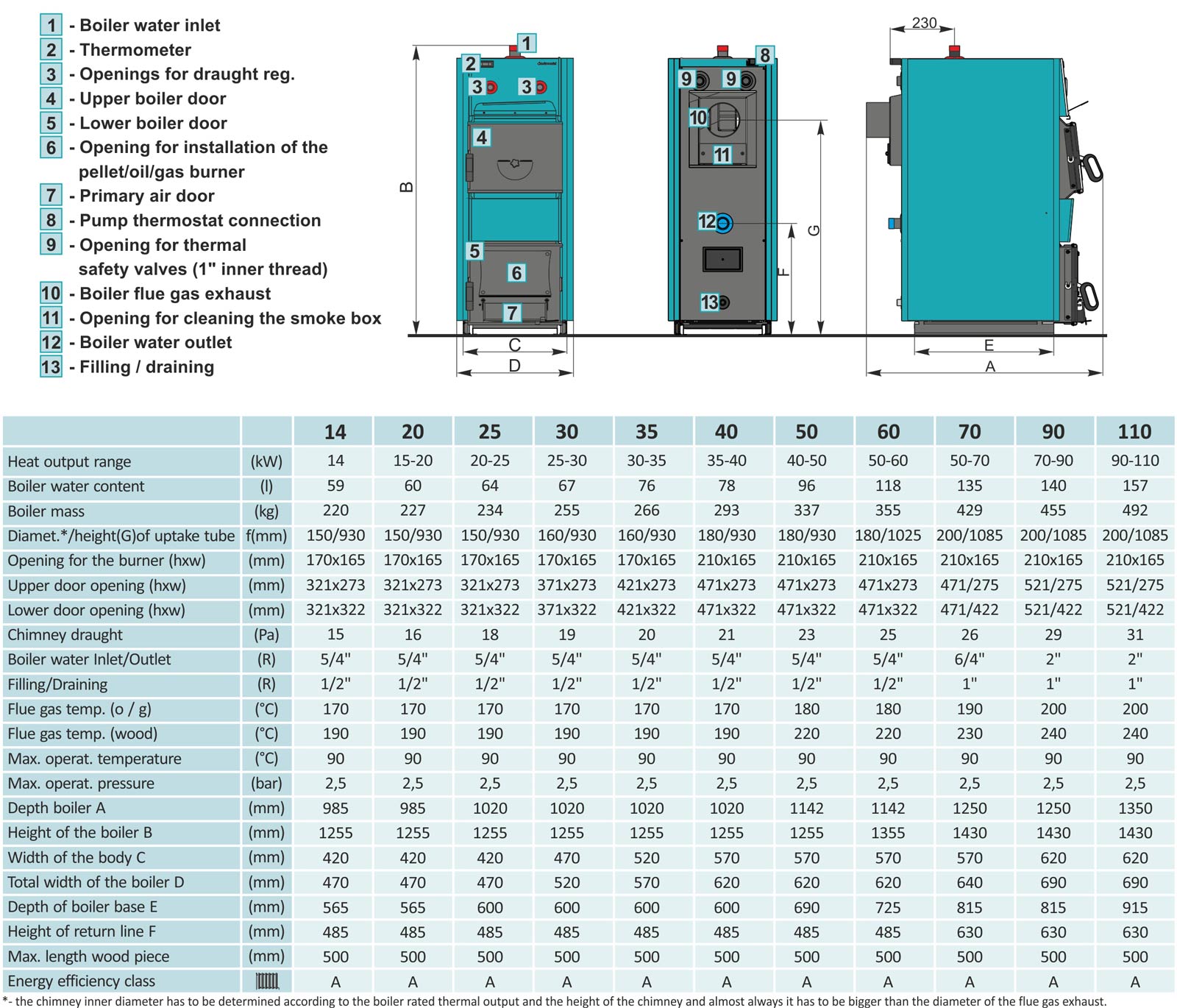

EKO-CK P (14–110 kW)

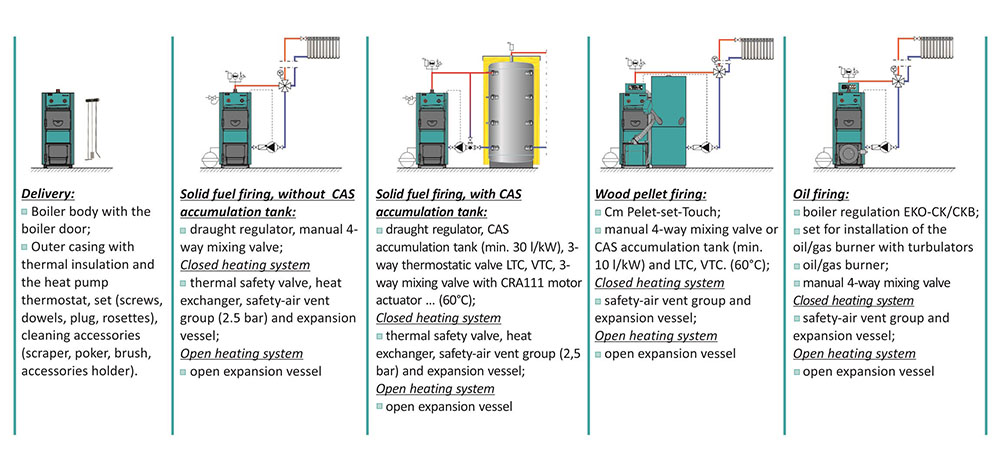

The EKO-CK P steel hot water boilers (with nominal heat output 14 – 110 kW) are engineered for solid fuel, wood pellet or oil firing to meet heating demands from the smallest to the largest premises, as a main or as an alternative heat source. This product can be easily recognized by its modern design, by its synthesis of modern technologies and its quality of material, as well as through its simple and easy assembly and its straightforward operation and control.

The application of well developed and thoroughly tested technical solutions makes these boilers safe and reliable. A particular feature of these boilers is the ease of integration of any suitable burner and boiler controls. Boilers are manufactured to the EN 303-5 standard.

PRODUCT CHARACTERISTICS

VERSATILE

Designed for combustion with several types of fuel (solid, pellets, liquid).

ECONOMICAL

Keeping the combustion gases in the three passages ensures a high degree of boiler utilization.

THERMOSTAT

The boilers are factory equipped with a thermostat that controls the operation of the pump.

INSTALLATION

A separate body of the boiler is supplied, with a separate thermal insulation panel, allowing easy transportation and installation.

- Hot water boiler for central heating systems is produced for solid fuel, pellets or oil firing (nominal heat output 14 – 110 kW).

- A carefully sized combustion chamber with triple pass flue gas flow assure boiler operation at high efficiency. This makes the boilers very economical to use.

- The combustion chamber is made out of high quality 5 mm thick steel sheet.

- The large door and combustion chamber enable firing with big pieces of wood, as well as easy cleaning and maintenance.

- If required a thermal safety system can be built in through already prepared apertures.

- A thermostat for pump control is built in.

- The body of the boiler is delivered separately from the casing and the thermal insulation which enables easier transportation and assembly with reduced risk of damage.

- The basic standard boiler is delivered with a boiler water temperature gauge as well as a cleaning set with an ashtray.

- In the Cm Pelet-set of the boiler fired with wood pellets, there is a set for installation of a pellet burner on the lower boiler door, turbulators, a pellet burner, pellet container, pellet feeder and boiler regulation.

- Boilers for oil firing are delivered with an appropriate aperture on the lower door to take the burner.

- Boilers for pellet firing require the appropriate lower boiler door to be delivered, together with the necessary pellet set (Cm pelet-set).

- When firing oil or pellets, turbulators must be installed in the boiler (factory delivery with Cm Pelet-set, additional order for firing oil).

- The basic boiler regulator control unit of the burner (for oil firing) is delivered separately. It can be connected via the upper casing lid of the boiler.

- The boiler is tested and certified to the European standard EN 303-5 and EN 304 and manufactured in accordance with ISO 9001 and ISO 14001 standard.