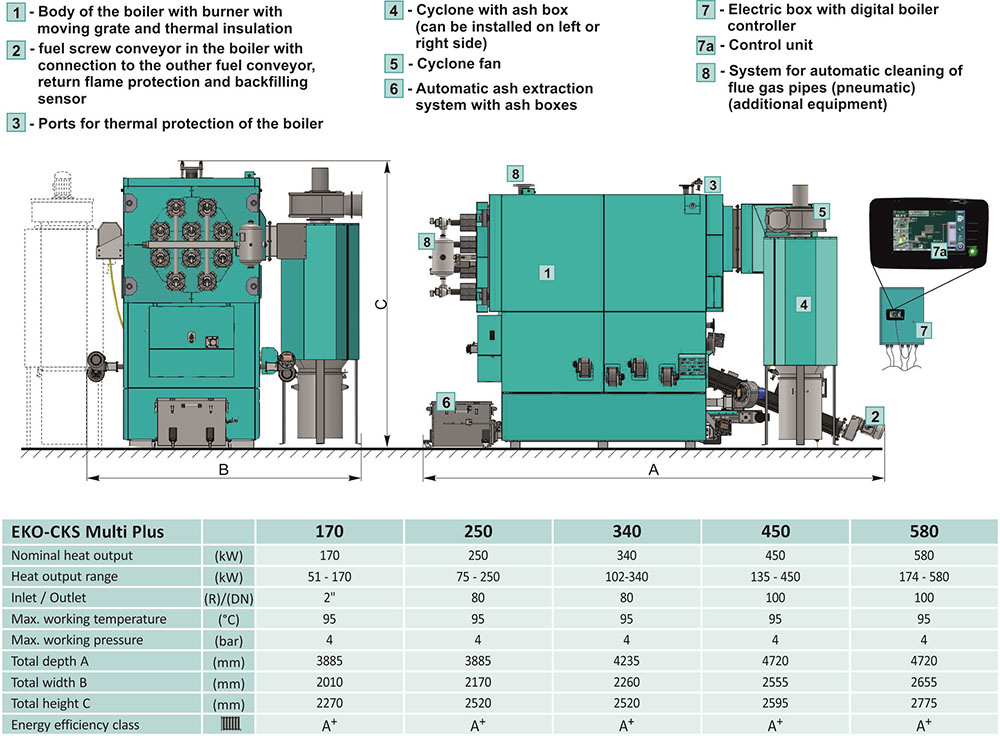

PRODUCT CHARACTERISTICS

ADDITIONAL EQUIPMENT:

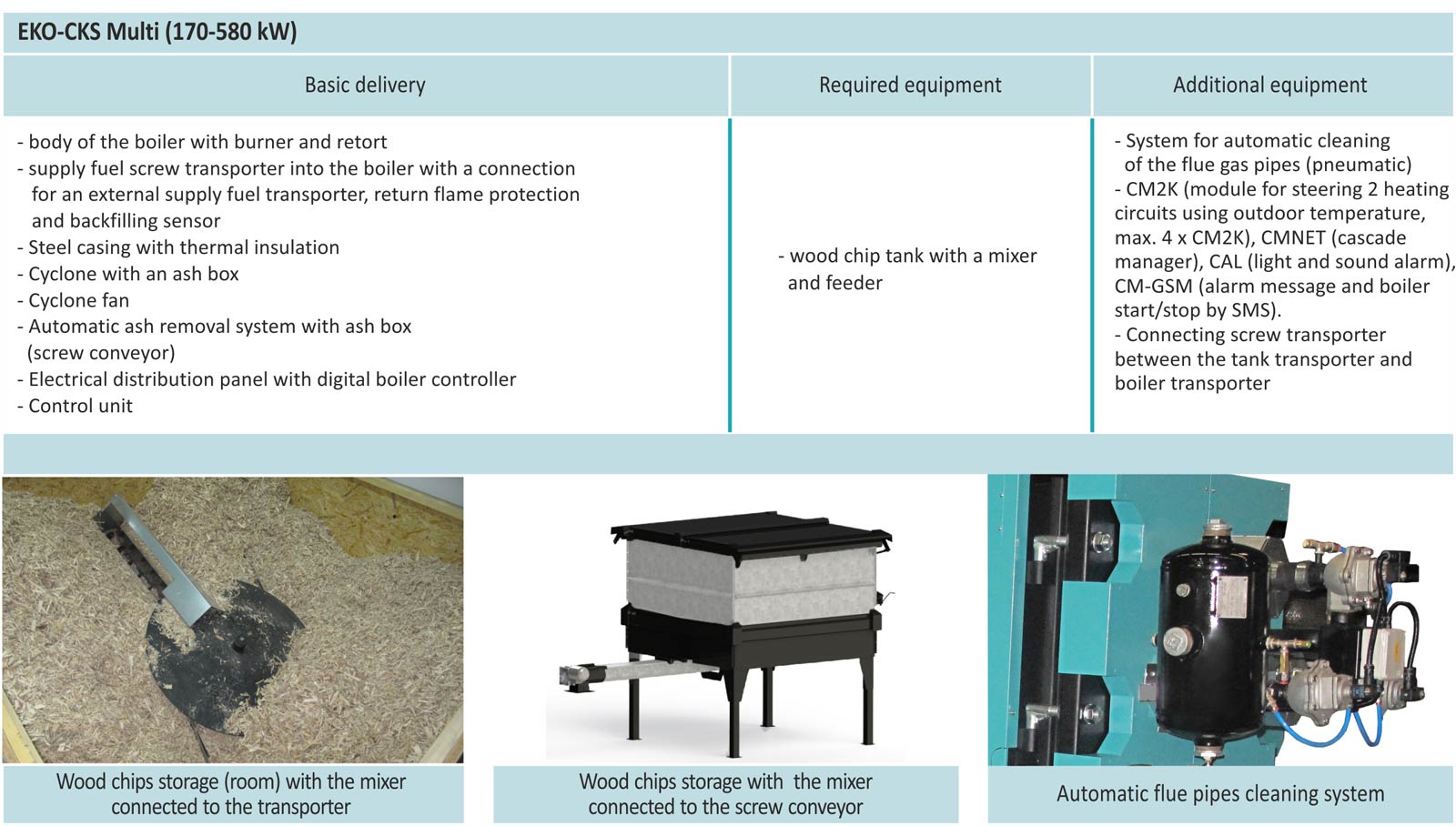

– system for automatic cleaning of flue pipes (pneumatic)

– automatic flue pipes cleaning system (pneumatic).

– CM2K (module for steering 2 heating circuits using outdoor temperature, max. 4 x CM2K), CMNET (cascade manager) CAL (light and sound alarm), CMGSM (alarm message and boiler start/stop by SMS).

– system for monitoring the boiler operation via PC, tablet or mobile phone.

– automatic flue pipes cleaning system (pneumatic).

– CM2K (module for steering 2 heating circuits using outdoor temperature, max. 4 x CM2K), CMNET (cascade manager) CAL (light and sound alarm), CMGSM (alarm message and boiler start/stop by SMS).

– system for monitoring the boiler operation via PC, tablet or mobile phone.

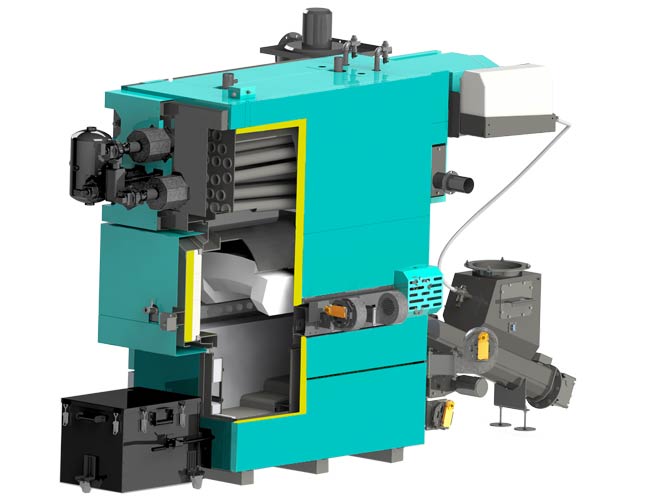

- Corresponding burner with moving grill provides for high boiler efficiency level which makes it economical.

- Maximal work pressure of the boiler is 4 bar which makes it possible to be installed in bigger heating systems.

- Separate delivery of boiler body, cyclone with fan, automatic ash removal boxes, thermally insulated casing, power distribution cabinet with digital boiler control and cleaning set which enables easy transport, installation in the boiler room and lower damage risk.

- The boiler is manufactured in accordance with the standard EN 303-5:2012.

TECHNICAL INSTRUCTIONS:

OBLIGATORY EQUIPMENT

– connecting fuel conveyer.

– fuel storage: wood chips with mixer and transporter / wood pellets with transporter.

– hydraulic separator or accumulation tank.

– fuel storage: wood chips with mixer and transporter / wood pellets with transporter.

– hydraulic separator or accumulation tank.